Al Davignon, ski design engineer

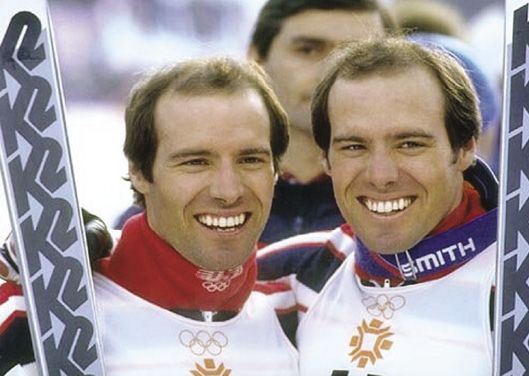

At the top of their careers, Phil and Steve Mahre depended on his skis.

For about a dozen years, starting in 1976, Al Davignon was the most influential ski designer in North America and, perhaps, in the world. He created a generation of K2 race skis for Phil and Steve Mahre, who won Olympic medals and World Cup races on the skis he built. Few Americans can say that. The skis he created were widely imitated by other factories around the world.

Davignon learned to ski at age four, in North Adams, Massachusetts. “My mom worked at home as a seamstress,” he says. “I was always underfoot, so she kicked me out of the house. She dropped me off at Dutch Hill, a ski area about three miles away. No one else in the family skied, but I didn’t mind.”

That was in 1954. By high school, Davignon was racing Class A giant slalom and downhill. He was captain of the ski team and a skimeister (four-event competitor). Off snow, he captained and quarterbacked the football team and played second base on the baseball team.

In January 1969, Davignon broke his right leg, then his left leg a year later. At age 19, he retired from FIS competition but not from ski racing. In 1971, during the early years of NASTAR, Davignon won the national championship. “It was an all-expenses paid trip,” he recalls. “That year the nationals were at Mount Snow, Vermont, just 50 miles from North Adams. They gave me $5 for gas.”

In 1972 Davignon entered Rensselaer Polytechnic Institute to major in biomedical engineering. He ski raced and coached, fielding a strong Division II East team in jumping and Alpine. Davignon earned a master’s degree in 1974 but stayed to work on a doctoral dissertation: designing an artificial replacement for the anterior cruciate ligament. And he was a NASTAR pacesetter at Jiminy Peak, with a 3 handicap.

By 1976 Davignon was ready to marry his high-school sweetheart, Denise Renton, and needed a job. He sent 20 resumés to hospitals and 10 to ski factories. Two offers came in, one from a Seattle hospital and one from K2. “K2 promised to pay my expenses to move to Seattle,” he says. “So I wound up in the ski industry.”

That year K2 was working hard to develop a new line of racing skis, under the direction of Bucky Kashiwa (brother of Hank Kashiwa), with assistance from Jean-Claude Killy. “Killy likes to sight down the length of the ski,” Davignon says. “He gets an idea of the ski’s flex pattern by looking along the edge while he presses the middle of the ski with his foot. It was his idea to draw a graph of the ski’s flex pattern.” He continues, “My first project was to design a machine to measure ski flex at every inch along the length and plot it. We looked at those bending curves and compared them to what we learned in on-snow testing. There are separate target curves for GS, slalom and downhill skis. The first skis designed using the curves were the 710 and 810 slalom and GS racers.”

Davignon began working with the Mahre twins in 1977. “At first they were skiing on the wood-core 710, which had a balanced flex pattern,” he recalls. “They said the tail was skidding, and there was no energy coming out of the turn, so we made the tail stiffer. That seemed to help.”

In 1978, Davignon took over K2’s design department. The first production ski he supervised was the 712. In the meantime, he was working fast and furiously in the race department, keeping the Mahres on competitive skis. “In May of 1979 we made 25 different pairs of slalom skis and went to Mount Bachelor to test them,” he says. “I always skied with the Mahres in order to feel for myself what they were telling me. We came back with two workable constructions, both with stiff tails, soft shovels and foam cores. One was all fiberglass. The other had a torsional reinforcement of carbon fiber. We built five more pairs of each and took them to New Zealand. Phillip and Steven settled on the all-glass ski, which became the 710 FO. The carbon ski was just too radical.”

The 710 FO had a continuous steel edge. In 1980 Davignon built a version with the cracked edge originally developed by Dynamic for the VR17 and widely adopted for slalom racers. That softer-flexing edge allowed him to add thicker layers of fiberglass to make the ski torsionally stiffer. “It was an immediate success,” he says. “All through 1980 and 1981 the Mahres skied on the cracked-edge VO. We held three successive testing camps and couldn’t improve on it.”

Development of a world-class giant slalom ski went in another direction. In 1978 Steve Mahre won the World Cup GS at Stratton, Vermont, skiing on the wood-core 810, which had layers of aluminum inside K2’s traditional fiberglass torsion box. In 1979 the twins tried a foam-core version and found it too slow, so K2 made the shovel firmer to bring the ski around faster. In 1980 Davignon built K2’s first laminated GS skis, but by midseason the Mahres were back on their wet-wrap EL skis—basically, a foam-core fiberglass design with 15-inch sheets of aluminum in the tip and tail for stability. “At that point the boys were skiing GS by going straight at the gate and then making a turn,” Davignon says.

During the summer of 1981, Phil Mahre came up with the idea of combining the EL and 812 aluminum-sandwich constructions. Davignon built a few pairs, with short aluminum plates at the tip and tail plus a single full-length sheet inside the wet-wrap box; he called it the EL Combi. “Steven switched to the Combi and won three giant slaloms that winter, including the world championship,” Davignon recalls.

After the Mahres retired in March 1984, Davignon redoubled development of recreational models. The 5500 Unlimited, introduced that year, was an offshoot of the racing program, with the cracked edge. It was a soft-flexing ski that could hold a carved turn on hard snow. Davignon went on to create versions of that ski and the VO with new lightweight, high-strength materials like Kevlar and ceramic fibers. Under his management, engineer Lou Fazio developed the triaxial braiding system, which wove a thin, strong sleeve of fiberglass around the fir-and-spruce core.

By the time Davignon left K2 in 1988, his wife was a registered nurse, and the couple had two kids, Kristen and Harrison. The family stayed in Burien, Washington, while Davignon consulted on snowboard projects for Lamar (owned by Look) and Aggression (owned by Volant). He then went back to his academic specialty and launched a biomedical career, using the newly emerged CAD/CAM technology to improve surgical implant devices. Davignon retired in 2020.

Seth Masia is president of ISHA. He first interviewed Al Davignon in 1984.